PU Lathe Cage and Metal Polishing Machine Disc

At Vibra Finish Solution, we provide precision PU (Polyurethane) lathe turning services for tumbling barrels and polishing discs used in metal finishing machines. This process restores surface flatness, profile accuracy, and smoothness, ensuring your equipment operates at peak efficiency.

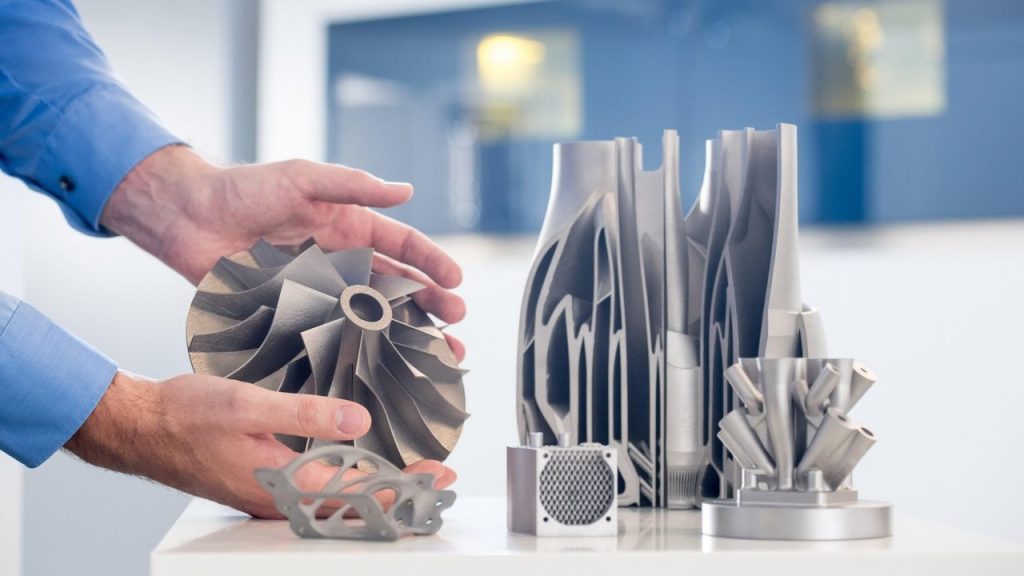

PU Lathe Turning for Tumbling Barrels

Tumbling barrels are critical in metal finishing, where parts are vibrated and rotated for surface smoothing. Our PU turning service re-machines worn liners, dividers, and working surfaces to restore the original spiral flow path, guaranteeing consistent part movement and polishing results.

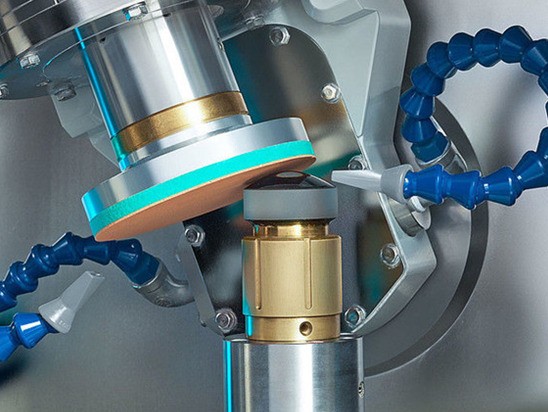

PU Lathe Turning for Polishing Discs

Polishing discs are key contact points in finishing machines. We machine PU discs to precise specifications, restoring or fabricating new profiles that improve polishing efficiency, extend service life, and ensure stable machine operation.

Why PU Lathe Turning Matters

The flatness and accuracy of PU surfaces directly impact machine performance. Even minor wear or profile deviation can cause:

-

Product jamming

-

Uneven polishing results

-

Extended cycle times

-

Inconsistent surface finish

Our precision PU lathe process eliminates these issues, bringing your machine back to OEM condition.

Benefits of PU Lathe Turning

-

Higher efficiency – Restores correct flow path for smooth, obstruction-free part circulation.

-

Consistent quality – Flat, uniform PU surfaces ensure even finishing across every batch.

-

Extended liner life – Reprofiling distributes wear evenly, slowing down deterioration.

-

Reduced noise & vibration – PU’s properties stabilize machine performance and improve the work environment.

Our PU Lathe Turning Process

-

Inspection & Measurement – Detailed evaluation of wear and profile accuracy.

-

Programming & Mounting – Careful setup on our dedicated PU lathe with precise technical parameters.

-

Precision Machining – Skilled technicians turn PU surfaces to restore standard or custom profiles.

-

Quality Control – Dimensional and surface checks against OEM specifications.

-

Finishing & Delivery – Cleaned, inspected, and returned in ready-to-use condition.

Why Choose Vibra Finish Solution?

-

Specialized equipment – Large-capacity PU lathes handle a wide range of barrel and disc sizes.

-

Expert technicians – Deep knowledge of hydrodynamics and finishing process design.

-

Guaranteed accuracy – Profiles restored exactly to OEM or custom requirements.

-

Complete solutions – We offer PU Turning + PU Coating for total equipment refurbishment.

👉 If your polishing machine is losing efficiency, jamming, or producing uneven results, worn PU surfaces may be the cause.

📞 Contact Vibra Finish Solution today for expert consultation and a tailored restoration plan!

Phone: (417) 379-9784

(417) 987-0008

Email: Sales@vibrafinishsolutions.com

Engineering@vibrafinishsolutions.com