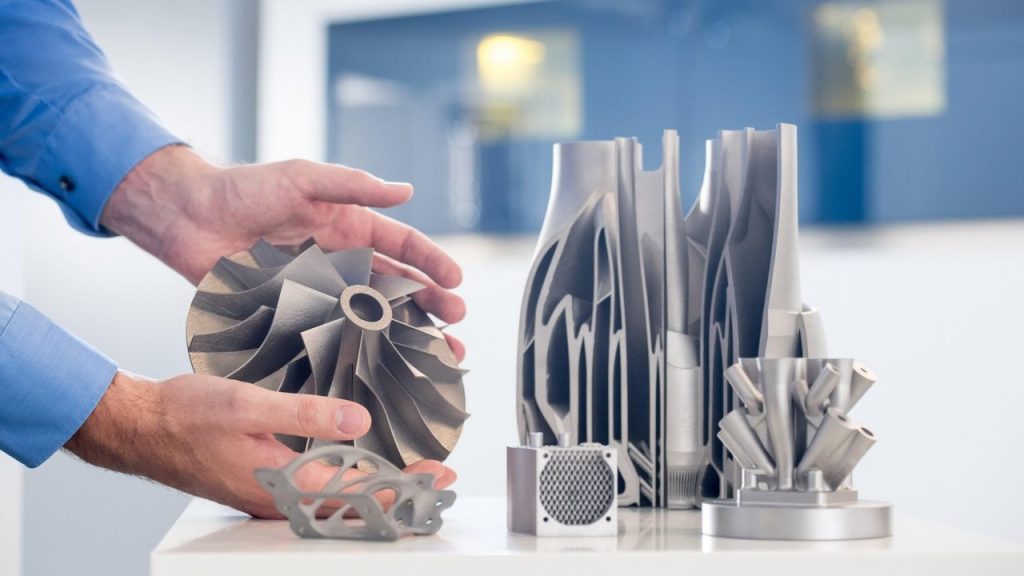

PU coating service for metal finishing machine cages and discs

The vibration finishing machine is a core piece of equipment in any metal surface treatment line. The PU (Polyurethane) lining inside the machine cage and disc plays a critical role in determining both operational efficiency and the quality of finished products.

Over time, wear, peeling, or cracking of the PU lining is inevitable. If left unaddressed, this deterioration can lead to:

-

Reduced product quality: Scratches, impacts, and lower gloss diminish the aesthetics of the finished product.

-

Shortened equipment lifespan: Direct friction and impacts on the metal cage can cause structural damage, leading to costly repairs or replacement.

-

Increased operating costs: Excessive wear increases consumption of grinding media and chemicals, generates noise, and affects the working environment.

Vibra Finish Solution’s professional PU Coating Service provides a cost-effective solution to restore your equipment and maintain optimal production quality.

Benefits of Our PU Coating Service

-

Protect Product Quality: High-quality, elastic PU lining minimizes direct impact during polishing, ensuring smooth, defect-free surfaces with consistent gloss.

-

Extend Equipment Lifespan: Using imported PU materials with superior abrasion and chemical resistance, the new coating protects the cage and disc, prolonging equipment life.

-

Save on Costs: PU lining replacement is far more economical than replacing the entire machine cage, reducing maintenance budgets and avoiding costly downtime.

-

Increase Operational Efficiency: Restored PU surfaces reduce processing time, improve productivity, and ensure consistent quality across batches.

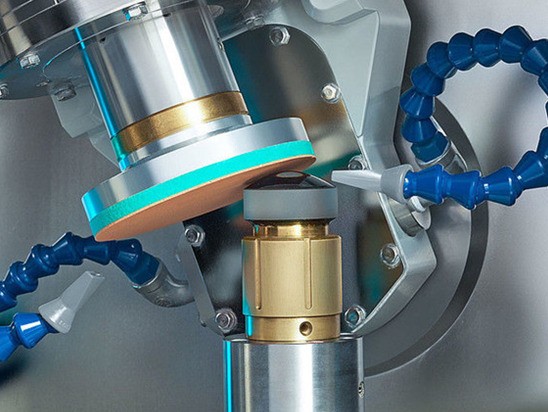

Our 5-Step PU Coating Process

-

Reception & Survey: Inspect and assess the current PU lining condition.

-

Surface Preparation: Remove the old PU layer and treat the metal cage surface for maximum adhesion.

-

PU Coating Application: Apply advanced hot casting technology for a uniform, durable, and seamless PU lining.

-

Finishing: Precisely machine the vulcanized PU surface to achieve the correct shape and thickness.

-

Inspection & Delivery: Perform strict quality checks and provide a clear warranty before handover.

Why Choose Vibra Finish Solutions?

-

Proven Expertise: Over 20 years of experience in machinery and metal surface treatment technology.

-

Superior Materials: High-quality imported PU with full technical specifications.

-

Advanced Techniques: Use of modern, effective PU construction methods.

-

Dedicated Service: Committed to customer satisfaction, timely completion, and professional guidance.

Protect your assets and maintain production efficiency—contact us today for expert advice and a competitive quote.

Phone: (417) 379-9784

(417) 987-0008

Email: Sales@vibrafinishsolutions.com

Engineering@vibrafinishsolutions.com