Maintenance - Restoration of finishing deburring machine, dryer

Any production line relies on stability and continuity. Even a minor issue with equipment—such as vibrating polishers, centrifuges, dryers, or auxiliary machines—can seriously disrupt productivity and compromise product quality.

With decades of practical experience, Vibra Finish Solution, Inc provides specialized industrial machinery repair and maintenance services, responding quickly and accurately to all customer needs.

Our Services

1. Diagnosis & Troubleshooting

From simple problems like imbalance or grease leakage to complex issues with rotating mechanisms and electrical controls, our team quickly identifies the root cause of any equipment malfunction.

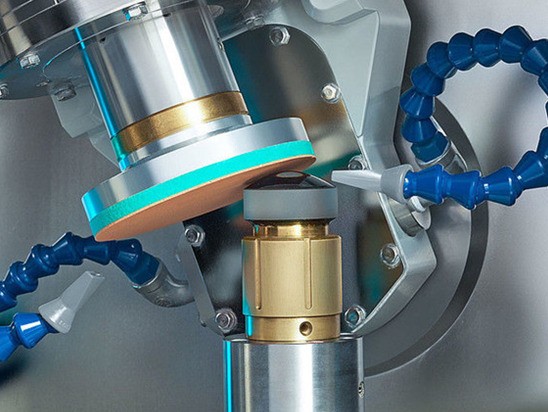

2. Replacement of Genuine Components

We supply high-quality spare parts, including motors, bearings, belts, sensors, and more, ensuring full compatibility and long-lasting performance.

3. Periodic Maintenance

We perform regular cleaning, lubrication, and transmission checks according to your operating cycles, keeping your machines in peak condition.

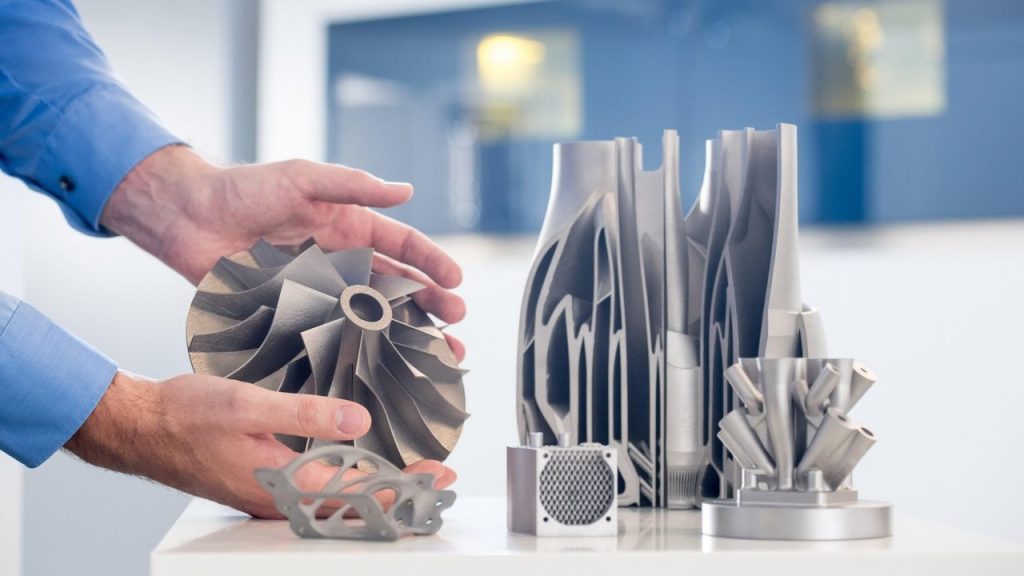

4. Equipment Optimization

Beyond repairs, we provide expert advice to improve operational efficiency, reduce energy consumption, and extend equipment lifespan.

Scope of Service

Our skilled technicians, with deep knowledge of surface treatment equipment, handle a wide range of machines and problems:

Equipment Types:

-

Vibration polishing machines (round cage, U-cage, etc.)

-

Industrial centrifugal dryers

-

Centrifugal spinners

-

Horizontal drum spinners

-

Other auxiliary production line equipment

Common Failures:

Mechanical Problems

-

Weak, noisy, or overheated main motors

-

Worn or damaged bearings and shafts

-

Broken or uneven shock absorber springs

-

Peeling or worn PU lining

-

Structural or frame issues

Electrical & Control Problems

-

Damaged control cabinets or inverters

-

Wiring shorts, starter or relay failures

-

Timer inaccuracies

Performance Problems

-

Weak or uneven vibration

-

Abnormal noise during operation

-

Dryers not heating properly or slow drying

Our Repair & Maintenance Process

-

Reception & On-Site Survey

Our technical team inspects your equipment on-site to assess its condition. -

Diagnosis & Quotation

We accurately determine the root cause and provide an optimal repair plan with a transparent, detailed quote. -

Repair & Replacement

Highly qualified technicians perform repairs using high-quality, compatible spare parts. -

Test Operation & Calibration

Machines are test-run, parameters checked, and re-calibrated to ensure stable, efficient operation. -

Handover & Warranty

Equipment is handed back with operating guidance and a clear warranty on repaired or replaced parts.

Why Choose Vibra Finish Solution, Inc?

-

Accurate Diagnosis: 20+ years of experience ensures quick and precise problem identification, saving time and costs.

-

Quick Response: We prioritize urgent requests to minimize production downtime.

-

Quality Replacement Parts: Motors, bearings, inverters, and specialized components are always in stock.

-

Specialized Technical Team: Experts in electromechanics with deep knowledge of industrial polishing machines and dryers.

-

Reasonable Cost & Warranty: Competitive pricing with long-term warranty for peace of mind.

Don’t let equipment failure disrupt your production line.

At the first sign of unusual machine behavior, contact Vibra Finish Solution immediately for fast, professional, and reliable support.

Phone: (417) 379-9784

(417) 987-0008

Email: Sales@vibrafinishsolutions.com

Engineering@vibrafinishsolutions.com