MOST POPULAR METAL SURFACE TREATMENT METHODS TODAY

★ VITAL IMPORTANCE: Bare metal is never tough enough! Surface treatment is the **"rebirth"** process that gives metal a protective armor against corrosion, significantly boosting its mechanical strength and lifespan.

In the mechanical and manufacturing industry, **metal surface treatment** is not just an auxiliary step but a key factor determining the quality, durability, and aesthetics of a product. This article will delve into the most widely applied and effective methods today.

1. Principles & Benefits of Surface Treatment

Surface treatment involves creating physical, chemical, or mechanical changes on the outermost layer of the metal. The key benefits include:

- Corrosion Resistance: Prevents reactions with oxygen and moisture.

- Increased Hardness: Improves resistance to wear and tear, and impact.

- Aesthetics: Provides desired color and shine for design requirements.

2. Detailed Analysis of Popular Methods

2.1. Electroplating

Applications: Automotive components, industrial valves, high-end household appliances.

2.2. Anodizing (Aluminum Anodization)

Principle: An electrochemical process that creates a thick, hard, and durable **Aluminum Oxide (Al₂O₃)** layer on the surface of Aluminum materials. This porous layer allows for coloring.

Applications: Window frames, phone casings, semiconductor components, aircraft parts.

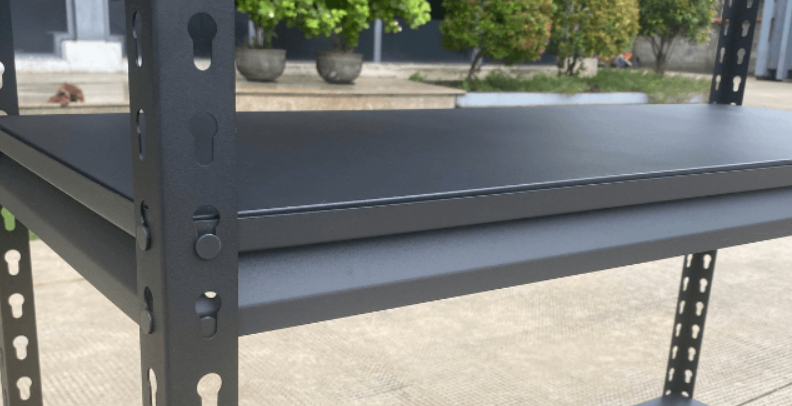

2.3. Powder Coating

3. Comparison Table & Selection Criteria

Selection Criteria: Always consider the **Base Material**, the **Intended Use** (corrosion resistance or increased hardness), and the **Budget** for optimal decision-making.

Conclusion

Surface treatment is a value-determining factor in the longevity of mechanical products. Choosing and applying the right technology not only makes products more durable but also strengthens your brand's position in the modern engineering market.